Introduction

Electrocatalysts are critical to increase reaction rates and control

selectivity in many electrochemical fuel production and consumption reactions.

In the Jaramillo Group, we develop new electrocatalyst materials for processes

including hydrogen evolution and oxidation, oxygen evolution and reduction, and

carbon dioxide reduction. These reactions are necessary for electricity generation

in hydrogen fuel cells, H2 production through water electrolysis, and

CO2 conversion to create useful fuels and chemicals. Our approach is

to understand the catalyst properties that control activity, selectivity, and

stability by combining catalyst synthesis and electrochemical performance

testing with physical and chemical characterization as well as computational

and theoretical modeling performed by collaborators. Using these insights, we

design new electrocatalyst materials with improved performance.

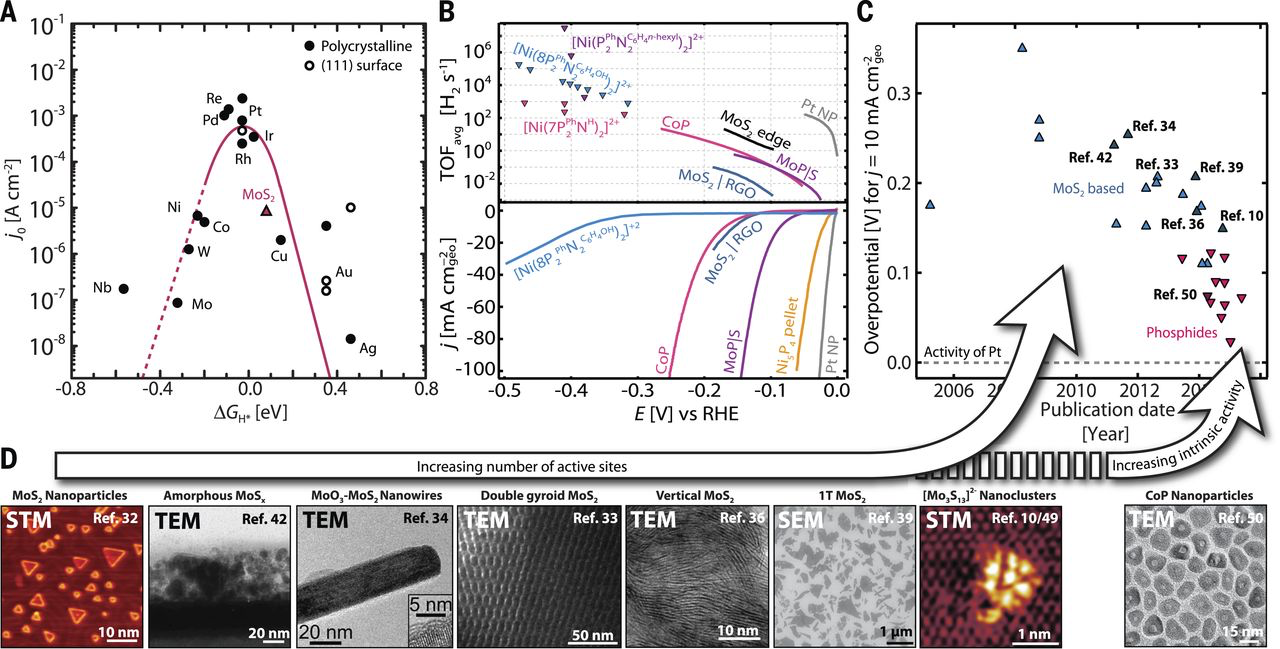

Hydrogen Evolution Reaction

The hydrogen evolution reaction (HER, 2 H+ + 2 e− → H2) is the

cathodic reaction in electrochemical water splitting. The HER is a classic

example of a two-electron transfer reaction with one catalytic intermediate,

and offers the potential to produce H2, a critical chemical reagent and fuel.

Driving the HER with renewable sources of energy can lead to a sustainable

source of hydrogen fuel that can stored, transported and used in a zero-emission

fuel cell of combustion engine. Achieving high energetic efficiency for water

splitting requires the use of a catalyst to minimize the overpotential necessary

to drive the HER. Platinum is the best known catalyst for HER and requires very

small overpotentials even at high reaction rates in acidic solutions. However,

the scarcity and high cost of Pt limits its widespread technological use. We

study the fundamental material properties that determine catalytic activity

for the HER. By designing new catalyst materials for the HER, we have expanded

our understanding of the surface structures and properties that govern HER

activity and stability. By applying this knowledge towards next generation

catalyst design, we have developed several earth-abundant HER catalysts,

including sulfide- and phosphide-based materials, with activities approaching

that observed for platinum.

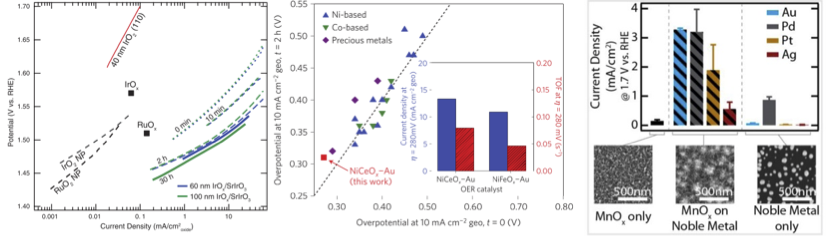

Oxygen Evolution Reaction

Image credits: L.C. Seitz et al., Science, 2016; Z.W Seh et al., Nature Energy, 2016; L.C. Seitz et al., J.Phys.Chem, 2015

The oxygen evolution reaction (OER, 2H2O → O2 + 4H+ + 4e-)

is the complementary anodic half reaction in electrochemical water splitting.

Requiring four proton and electron transfers per oxygen molecule, the OER is

the more complex of the two half reactions and is consequently responsible for

the majority of inefficiency in electrolyzer devices. In acidic media, only

Ir-based catalysts have shown high activity and stability for the OER. To reduce

dependence on expensive and rare precious metal catalysts, we aim to develop

higher performance, low Ir-content materials for the OER .

In alkaline media, catalyst material restrictions are relaxed and many first-row

transition metal oxides show high activity for the OER. We aim to developed high

performance OER catalysts , determine

to origin of enhanced activity through advanced characterization techniques ,

and incorporate high performance catalysts into devices .

The Jaramillo lab seeks to develop novel, high performance OER catalysts through

fundamental understanding of the structure-function relation of the catalyst surface

to enhance efficiency and promote increased commercialization of energy storage devices.

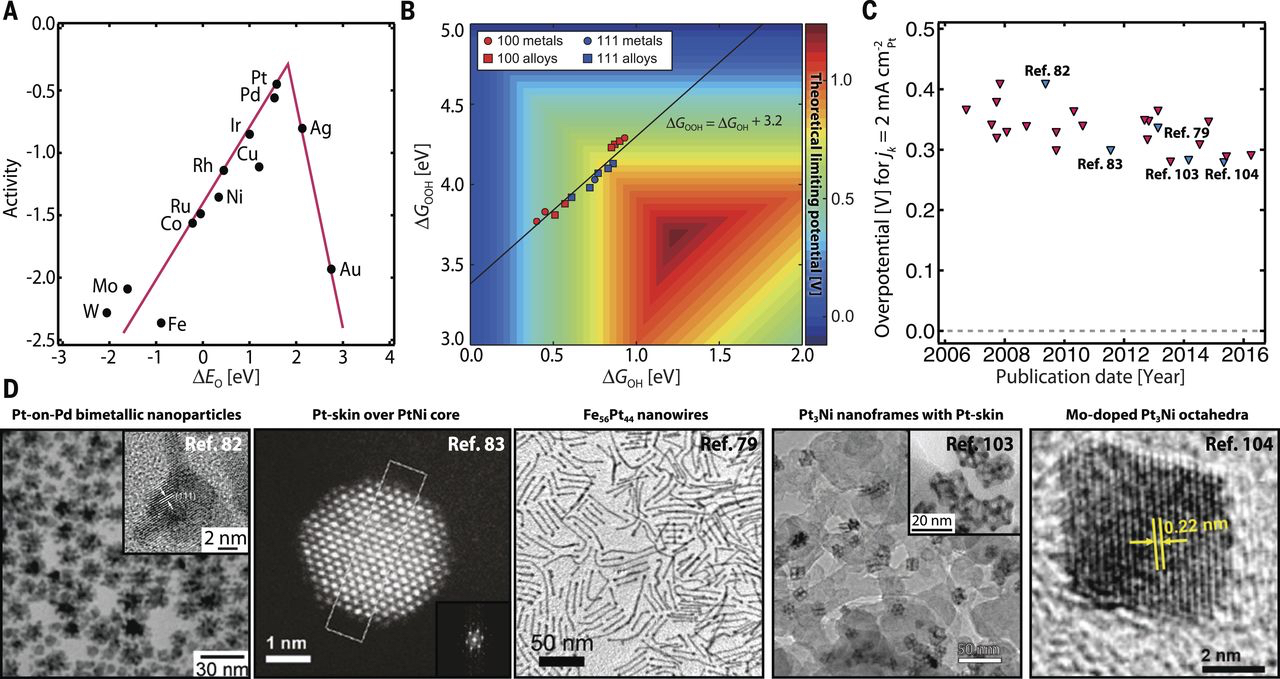

Oxygen Reduction Reaction

The oxygen reduction reaction (ORR) is a pertinent process in many electrochemical energy conversion and storage technologies, including fuel cells and rechargeable metal-air batteries. In acidic conditions, only platinum-based catalysts have shown sufficient activity and durability for practical purposes, although comes at a high cost and relies on limited global platinum supplies. Research in our laboratory focuses on designing improved activity ORR catalysts, with significantly reduced or eliminated platinum contents. Some strategies that have been employed to achieve this include the use of solid solution or intermetallic platinum alloys, shape controlled nanostructures to achieve preferential facet exposure, or the preparation of core-shell nanoparticles that can tune the interactions (i.e., binding energies) with ORR intermediate species. Our aim is to develop an improved understanding of the ORR process occurring on various surfaces, providing fundamental insight that can rationally guide our design of new catalyst materials.

Image credit: Z.W. Seh et al., Science, 2017

In alkaline conditions, the ORR is a much more facile process and

provides opportunity for non-platinum catalyst alternatives, including metal

oxides, nanostructured carbons and silver-based catalysts. The ORR process on

these surfaces is poorly understood in comparison to platinum, and the activity

still lags behind that of platinum on a turn over frequency basis. We aim to

develop new material designs and develop a thorough understanding of the surface

structures and properties that influence intermediate adsorption energies and ORR

activity on various alkaline-based catalysts.

The ORR can also proceed by a 2 electron reduction mechanism, forming hydrogen

peroxide species. While this is undesirable from an energy efficiency standpoint

for fuel cells (only 2 electrons transferred per oxygen molecule to form hydrogen

peroxide as opposed to 4 to form water), this electrochemical reaction is advantageous

because it could replace the energy intensive anthraquinone process conventionally

used to synthesize hydrogen peroxide. This electrochemical synthesis could, for

example, be coupled to renewable sources of energy (i.e., wind or solar) to

provide on site generation of hydrogen peroxide. As a powerful oxidizer,

distributed production of hydrogen peroxide could play an important role for

drinking water treatment or sterilization applications.

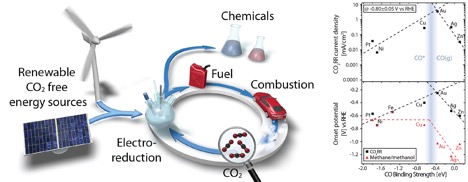

CO2 Reduction Reaction

Electrochemical reduction of CO2 has a potential of

becoming a major contributor to sustainable production of fuels and chemicals

through the use of renewable CO2 free energy sources. However, the

development of an effective catalyst is vital, as there are currently no industrial

scale operations that utilize this technology due to the low energetic efficiency.

In our group, we focus on gaining fundamental understanding of the surface chemistry

by tuning some of the key catalyst characteristics, such as the composition, the

surface structure, and the morphology, as well as other factors, such as electrolyte

composition and reaction conditions. By implementing the insights gained from our

work, we aim to design effective catalysts that would allow for the industrialization

of the technology.